Engineering Solutions: Automation, Electrical and Instrumentation

At Virtuoso, our multidisciplinary engineering team delivers Electrical, Instrumentation, Mechanical and Piping solutions that are robust, compliant and cost-efficient. We integrate feasibility studies, detailed design and procurement planning to ensure every project meets performance, safety and budget goals.

Engineering Services Offering

We provide end-to-end engineering services covering project evaluation, design, and execution support. Our expertise spans pre-bid and detail engineering, technical and feasibility studies, procurement, drafting, and due diligence to ensure precision and reliability at every stage.

- Pre-bid Engineering

- Detail Engineering

- Technical Studies

- Procurement Services

- Drawing Drafting

- Due Diligence

- Techno-economical Feasibility Studies

Engineering Disciplines

Process & Safety

Process design with HAZOP/SIL lifecycle to reduce risks.

Mechanical

Equipment sizing, specs, and layouts for rotating/static packages.

Piping

3D routing, isometrics, and stress analysis for constructible lines.

Civil & Structural

Code-compliant foundations, racks, and platforms engineered for reliability.

Electrical & Instrumentation

LV/MV power, instrumentation, and PLC/DCS/SCADA integration.

Software Tools

Software Tools

Disciline Offerings

Process & Safety Engineering

- Pre-bid Engineering/FEED/BEP

- Stand-alone Design

- Revalidation of Process Design

- Safety Studies

Mechanical Engineering

- Design of Static & Rotating Equipment

- Preparation of Equipment Drawings

Piping

Engineering

- Plot Plan

- Layouts, Isometric, 3D Modeling, Design & Calculations

- Piping MTO/BOM

Piping Stress

Analysis

- Simple & Complex Stress Analysis – Finite Element, Displacement, Cryogenic, FRP, Offshore

- Calculation

Civil

Engineering

- Site Preparation, Equipment Foundation, Drainage, Roads etc.

- Duct banks and culverts

Structural

Engineering

- Details Engineering

- Structural Stress Analysis

Electrical & Instrumentation

- Basic Preliminary Engineering

- Detail Engineering

Automation

We streamline processes through advanced automation technologies, enhancing operational efficiency and productivity.

Functional Detail Design

• FDS - Functional design Specification

• Controller & Server Loading Calculation

• SCADA -Supervisory Control and Data Acquisition

• PLC's - Programmable Logic Controllers

• DCS - Distributed Control Systems

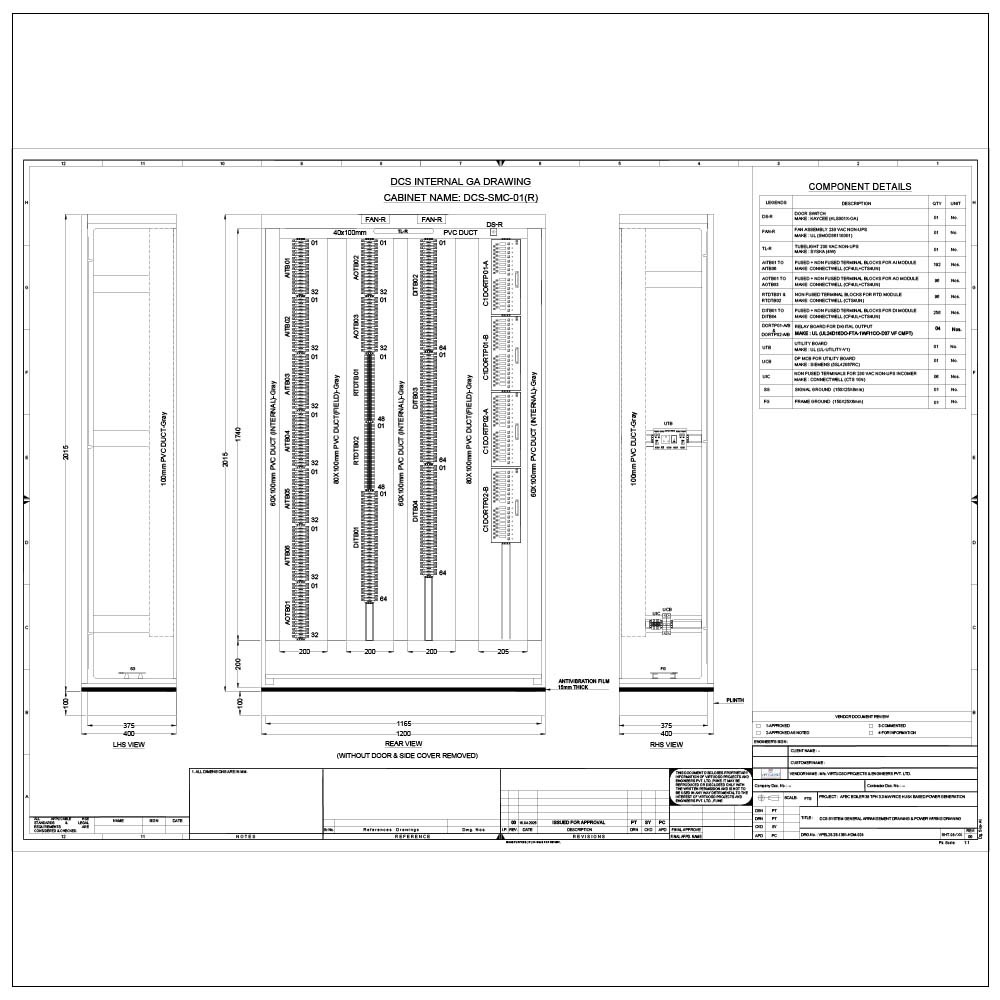

Hardware Engineering

• IO Assignment

• Wiring / Ferrule & Label Database

• Cabinet GA and wiring drawing (System, Marshalling

• Power Consumption & Heat Load Calculation

• Loop Drawings

• Wiring / Ferrule & Label Database

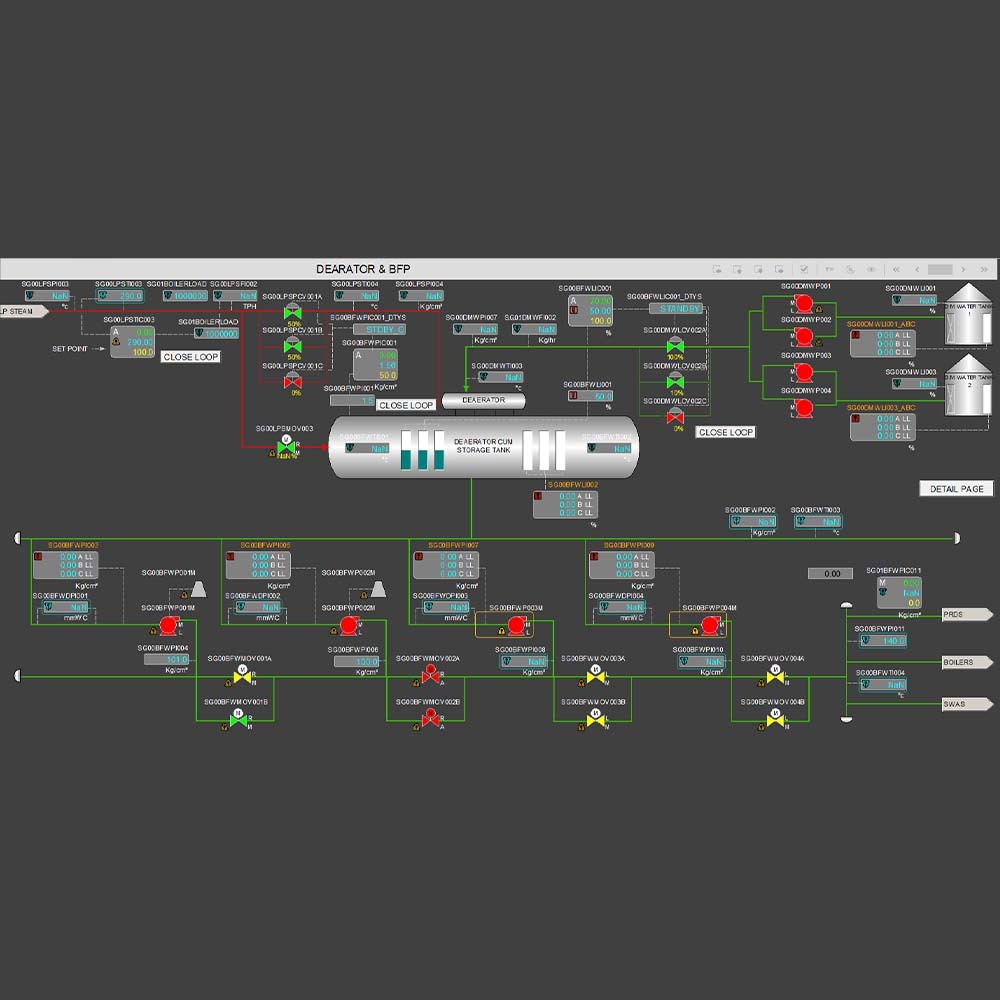

Software Engineering

• Logic Development, Loops, Complex Loops, Sequence Logic etc

• HMI / Graphics

• P&ID Marking for Static Development

• Dynamic Linking with Logic

• Shape Development –Shapes, Popups, Faceplates etc.

Functional Testing

• PreFAT & FAT process.

• Hardware Visual Checks, Loop Checks, Logic Checks & Puch points, Redundancy Checks etc

System Expertise

- EPKS C300 / C200, SM, SMSC

- TPS System - HPM, HG, LM

- Modular Systems - HC900, CE

- PLC, CE UOC, CE RTU, ML200

- S7 1200 / 1500

- S7 300

- S7 400H

- WinCC

- DeltaV Database

- DeltaV Operate

- DeltaV Live

- ControlLogix Series

- Compact Logix Series

- SLC Series

- Micro PLC

- ABB 800xA

Electrical

Our electrical engineering services encompass design, installation & maintenance of robust electrical systems to ensure safety & reliability.

- Outdoor Lighting, Floor Plan Layout

- SLD Preparation, Plant Indoor

- Standard Operation Processes

- AutoCAD & Microstation Drafting

- Testing & Commissioning Support

- Panel Designing -MCC, PCC, APFC

Instrumentation

We provide precision instrumentation solutions for monitoring and control, ensuring optimal performance across various applications. With a commitment to quality and customer satisfaction, we empower your operations to thrive in today’s competitive landscape

- Earthing , Loop Drawings , Datasheets preparation

- Termination Drawings , Tray Layout Preparation

- JB Schedule , Cable Schedule

- Erection Material Take Off (MTO), etc

- Hook-up Drawing Preparation

- Instrument index preparation as per P&ID