Optimize processes with Virtuoso’s engineering expertise and OTS, enhancing operator training for safe, efficient operations

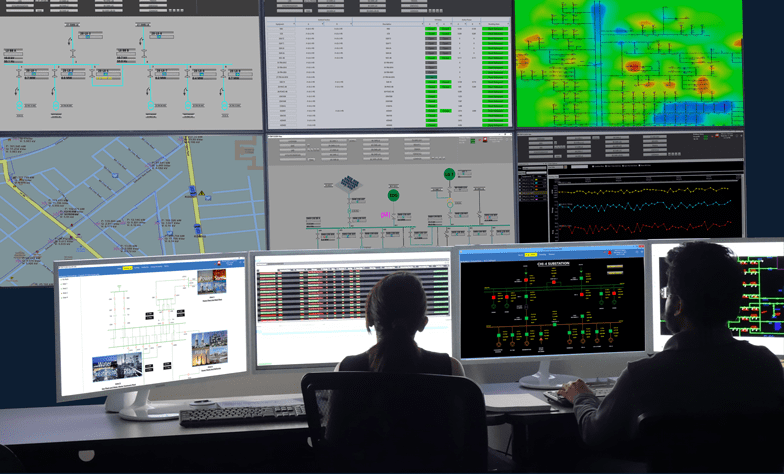

An operator training simulator (OTS) in process plants is a computer-based system used to train operators in handling various scenarios and operations within a plant environment. It mimics the behavior of the actual plant processes, allowing operators to practice different procedures, respond to emergencies, and familiarize themselves with the control systems without risking damage to equipment or harm to personnel

Key uses of training simulators are :

- Efficient operation of process plants by providing operators with realistic training experiences

- Operators skills enhancement

- Prevent plant tripping incidences

- Plant safety

Features

Scenario Training

OTS provides training scenarios that simulate normal plant operations as well as abnormal situations such as equipment failures, process upsets, and emergencies. Operators can practice responding to these scenarios in a safe and controlled environment.

Performance Evaluation

OTS can assess operator’s performance during training sessions, providing feedback on their decision-making skills, response times, and adherence to operating procedures.

Control System Simulation

It includes a replica of the plant’s control system, allowing operators to interact with it just as they would in the real plant. This involves monitoring process variables, adjusting setpoints, opening and closing valves, and initiating control actions

Plant Operation Training

OTS provides training scenarios that simulate normal plant operations as well as abnormal situations such as equipment failures, process upsets, and emergencies .It includes simulated plant operations for

- Cold start up

- Hot start up

- Emergency handling

Industries Served

Refineries

Petrochemical

Chemical

Power

Utilities

Services Offered

Projects

- LNG

- PFCC -PRU

- Isomerisation

- Hydrogen Gas unit

- Crude Distillation unit

- Vacuum Distillation unit.

- DHDT-Diesel Hydro treating Unit

- ONGC- MH -ASSET -ICP Complex

- HPCL- LNG up to Site Acceptance Test.

- NAYARA -Propylene recovery unit up to Model Acceptance Test.

System Expertise