How to Improve Panel Build Quality with Documentation

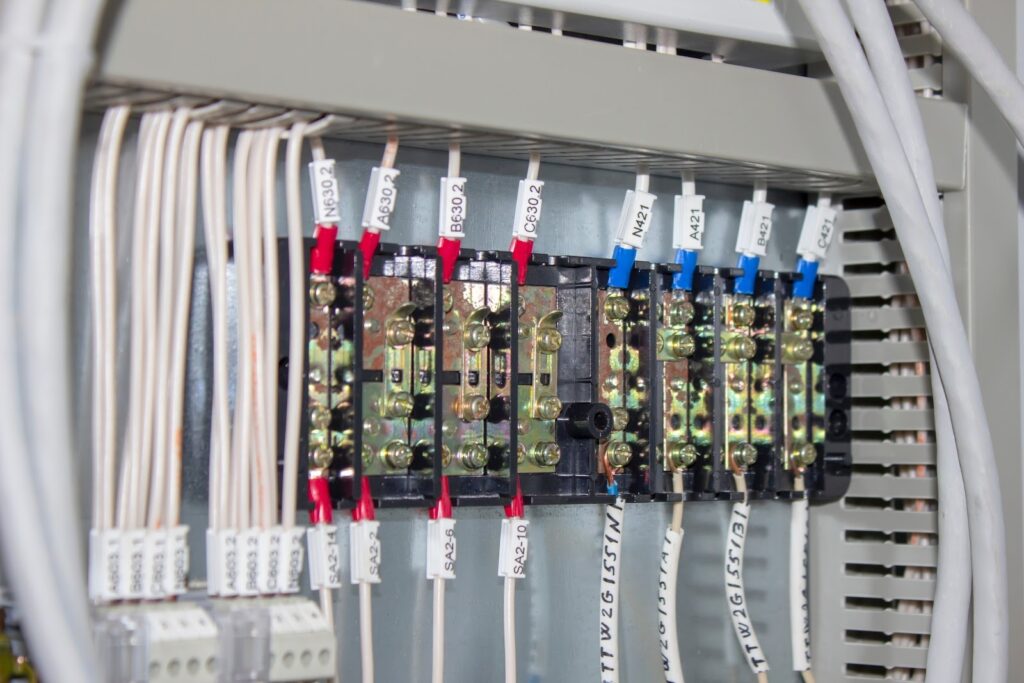

In my decades in this industry, I’ve seen two types of control panels. The first is a work of art: wires neatly routed in ducts, labels facing forward, and a clear logic that anyone with a multimeter can follow. The second is what I call the “spaghetti bowl”—a chaotic jumble of blue and grey wires where troubleshooting is a game of Russian roulette.

The difference isn’t just about the skill of the technician holding the screwdriver. It’s about the discipline of the engineering team before a single component is mounted. It’s about documentation.

At VPEL, we have long understood that a control panel is only as good as the paperwork that defines it. In an era where everyone is rushing to cut costs, many overlook the fact that documentation is not an administrative burden—it is a quality assurance tool. Here is how rigorous documentation elevates the build quality of industrial panels and why you, as a decision-maker, should demand it.

The “Blueprint” Approach to Manufacturing

Imagine building a house without a blueprint. You might get four walls and a roof, but the plumbing will leak, and the electrical outlets will be in the wrong places. The same logic applies to panel building. Quality cannot be inspected into a product; it must be designed into it.

Documentation serves as the single source of truth for the manufacturing floor. When a technician has a clear, approved set of schematics and layout drawings, the room for error shrinks dramatically. There is no guessing whether a wire should be 1.5 sq mm or 2.5 sq mm; the document dictates it. This standardization is the bedrock of consistency, and consistency is the definition of quality.

The Critical Documents You Cannot Ignore

To drive real quality, we need to move beyond basic line diagrams. A high-quality panel build relies on a suite of specific documents:

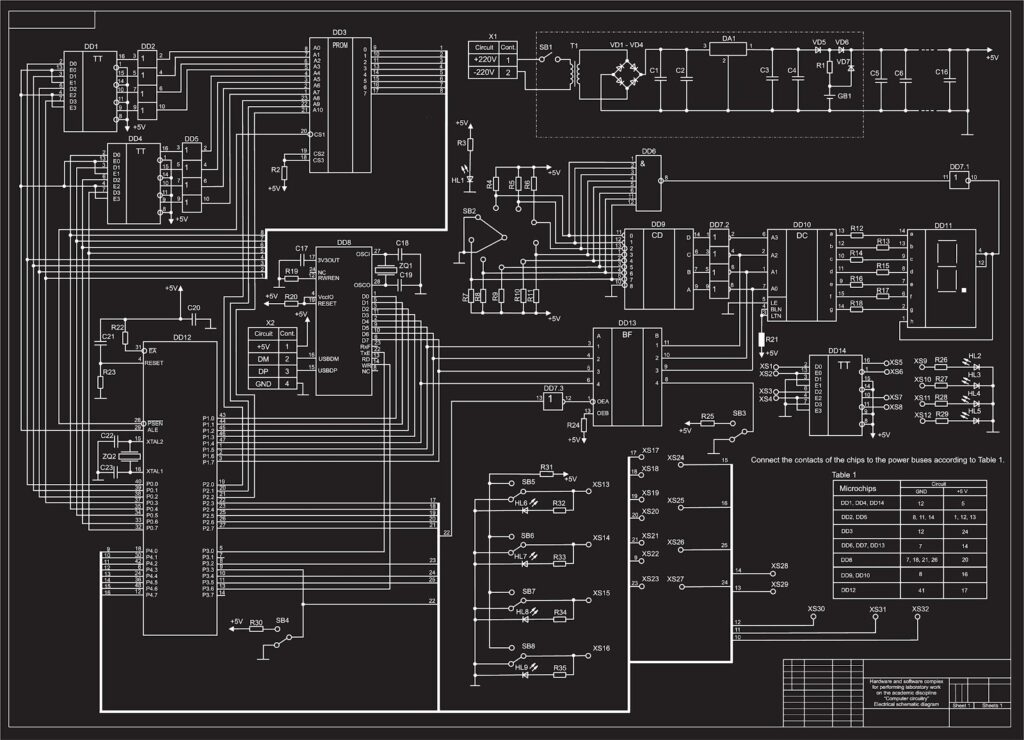

1. Comprehensive Electrical Schematics

This is the logic map of your system. Good schematics don’t just show connections; they show function. They should include wire numbers, terminal block details, and cross-references. When a schematic is detailed, the wiring process becomes efficient. A technician isn’t “figuring it out” on the fly; they are executing a plan. This reduces the risk of loose connections or crossed wires, which are the leading causes of early field failures.

2. The Bill of Materials (BOM)

A precise BOM is your quality gatekeeper. It specifies the exact make and model of every breaker, relay, and contactor. Without a strict BOM, production floors often substitute “equivalent” parts to save a few pennies or use what’s on hand. These substitutions often have different thermal properties or duty cycles, compromising the panel’s longevity. A locked-down BOM ensures that the engineering intent is physically realized in the final product.

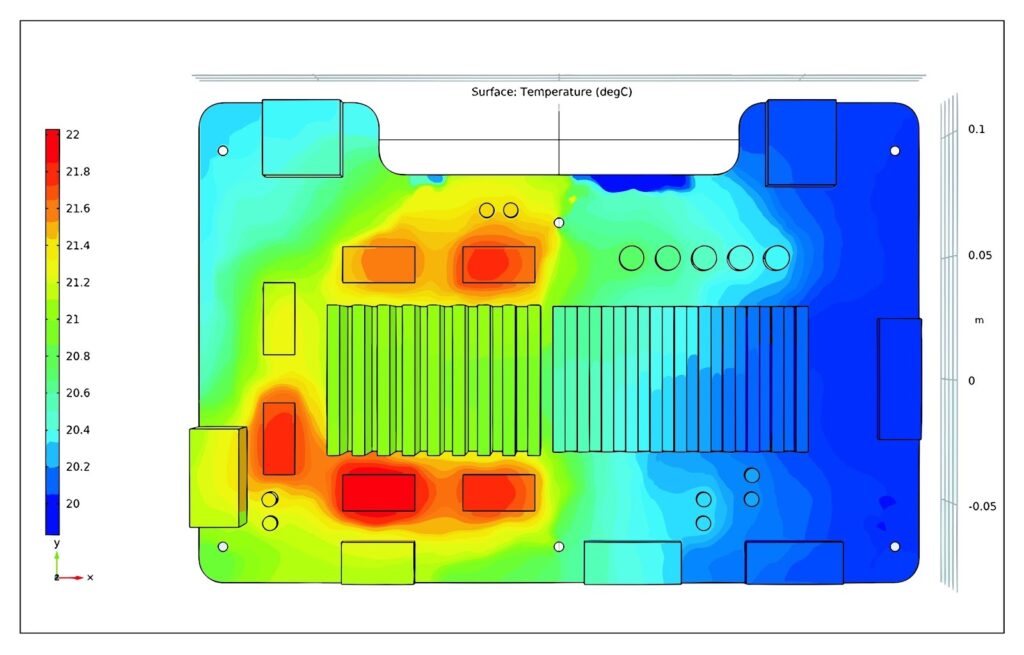

3. Panel Layout Drawings

Heat is the silent killer of electronics. A Variable Frequency Drive (VFD) or a PLC generates heat that must be dissipated. Layout drawings aren’t just about fitting everything in the box; they are about thermal management. They ensure components are spaced correctly for airflow and that high-voltage power lines are segregated from sensitive signal wires to prevent electromagnetic interference (EMI). A panel built without a layout drawing is a panel destined to overheat.

The Business Case: Why Documentation Pays Off

You might ask, “Why should I pay for all this engineering time? I just need the panel to work.” That is a short-term view that leads to long-term pain.

Reduced Downtime: When a machine goes down at 2 AM, the maintenance team’s best friend is the documentation. A well-labeled panel that matches the schematic allows for rapid fault diagnosis. If the documentation is poor or non-existent, hours are wasted tracing wires, costing you thousands in lost production.

Scalability and Replication: If you need to order five more identical panels next year, good documentation ensures they are actually identical. Without it, you are relying on the “tribal knowledge” of a specific builder who might have left the company.

Safety and Compliance: We operate in a world of strict standards. Whether it’s adhering to Indian Standards or international benchmarks, documentation provides the traceability required for audits. It proves that the panel was calculated to withstand the necessary short-circuit current ratings and that protective devices are coordinated correctly.

The VPEL Standard

At VPEL, we don’t just “build panels.” We engineer solutions. Our process is rooted in the belief that the physical product is the final output of a rigorous documentation phase. We know that when we hand over a panel, we are handing over a system that is safe, reliable, and maintainable for decades.

In the fast-paced world of industrial automation, it is tempting to cut corners. But remember: Quality is remembered long after the price is forgotten. Demand the documentation your operation deserves.